High Temperature Glass Fabrics

| Click on shortcuts below for specific items Scrim • Acrylic • Loomstate • Heat Treated • Graphite • Rewettable / Dip Coated • Vermiculite • Aluminium Foil Faced • Acrylic/Neoprene • Polyurethane • Silicone • Teflon • Silica • Pre-oxidized Carbon • Ceramic Fibre • Rubber | |

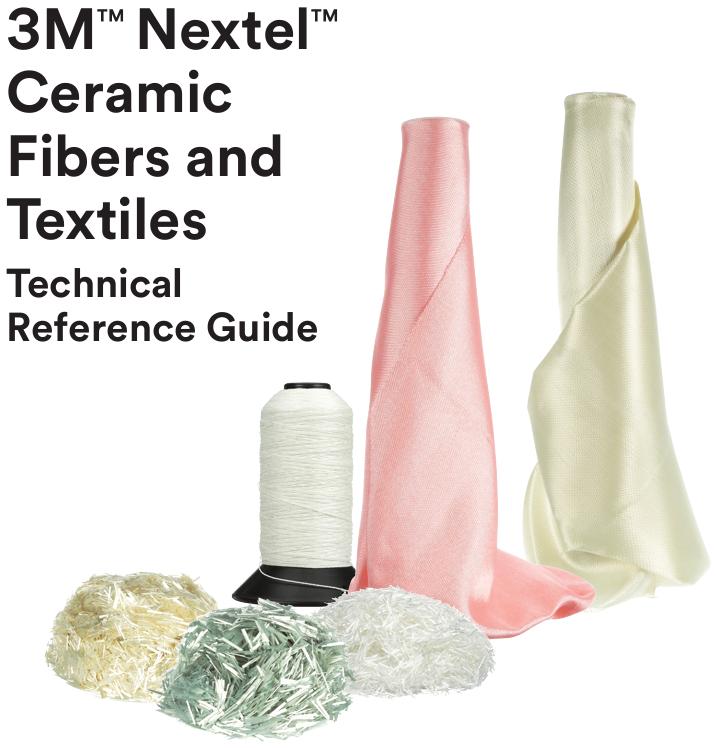

| Advanced Composite Fabrics (These are specialist indent items subject to MOQ) Darco Industries is also a specialist high temperature, glass fabrics and tapes for composite reinforcement, including E Glass, S Glass, 96% silica glass, 99.9% silica (Quartz) fabric, Alumina fibre and Alumina Silicate fibre such as European ALF and American 3M Nextel ultra-high temperature ceramic fabrics and fibres. |

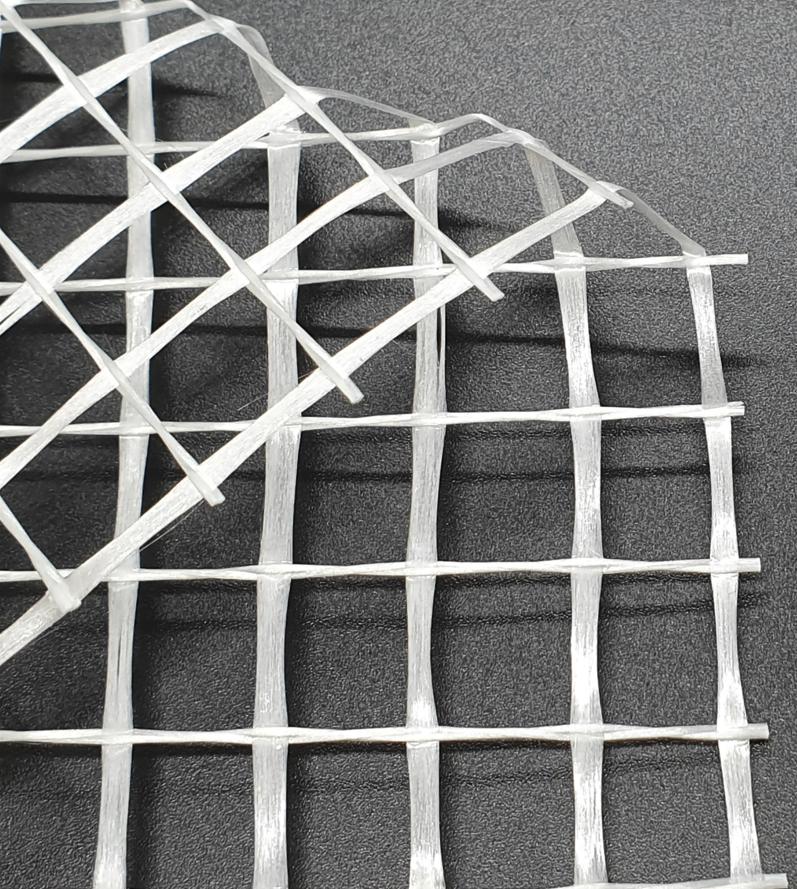

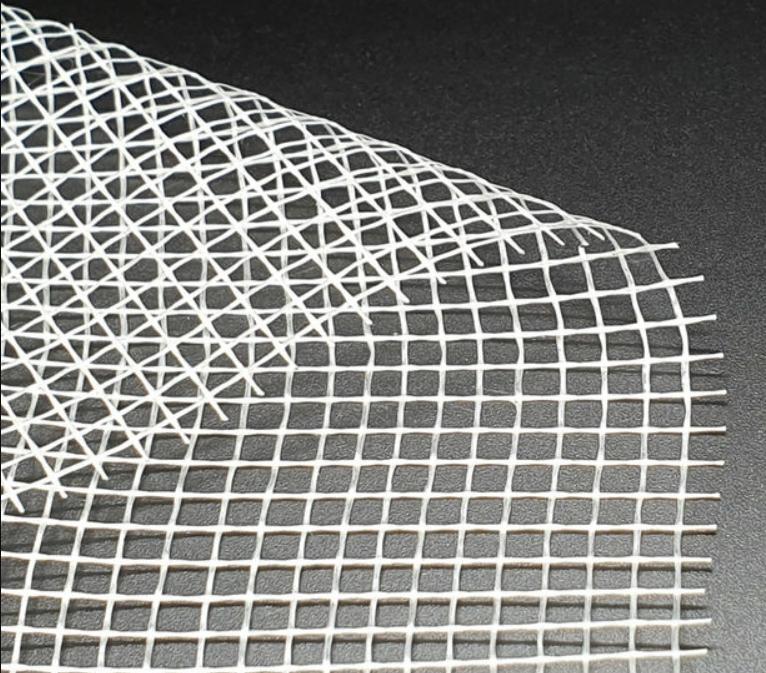

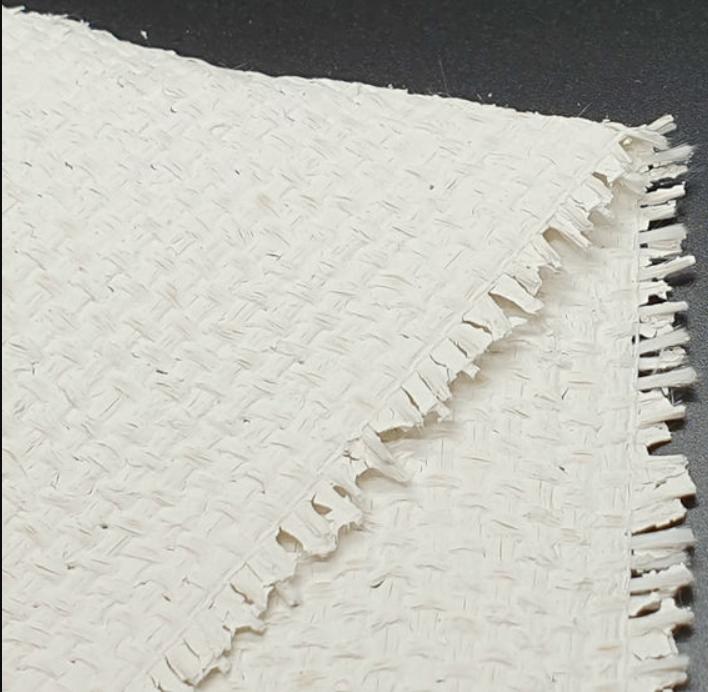

Scrim

Fiberglass scrim is a woven mesh used to add tensile strength and prevent cracking in construction, repair, and manufacturing.

Applications

- Drywall & Plaster: Reinforces joints and corners to stop cracks, providing a smooth, strong finish for walls and ceilings.

- Concrete: Adds strength to concrete for countertops, decorative elements, and structural components, preventing spalling and cracking.

- Mortar: Reinforces plastered mortar to control cracks and add durability.

- Tiles: Used as reinforcement for mosaic and marble pavements.

- Membranes & Foils: Reinforces roofing membranes, vapor barriers, and aluminum foils for increased strength and puncture resistance.

- Composite Materials: Laminated with resins (epoxy, polyester) to strengthen fiberglass, plastics, and other materials, even in complex shapes.

- Insulation: Used as a facing or basic cloth for thermal and acoustic insulation.

- Packaging: Reinforces products in the packaging industry

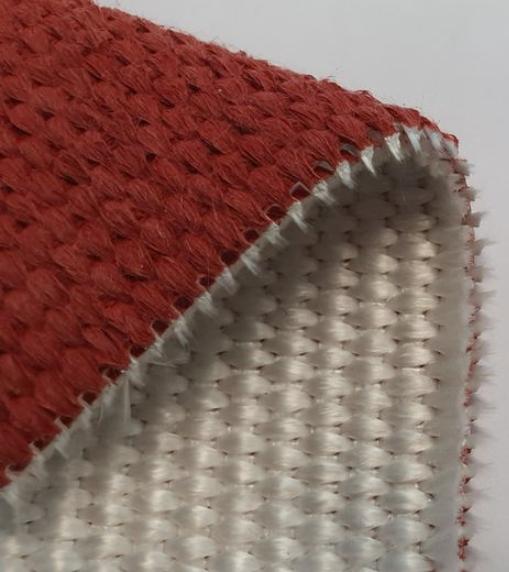

Acrylic Coated

E-Glass Fabric with Acrylic Coating is used for high-temperature insulation, fire protection (like welding blankets/curtains), protective covers, expansion joints, and machinery jackets.

Offering heat, spark, and chemical resistance while minimizing fraying and shedding for safer handling in industrial settings like metal processing, power generation, and construction.

Its combination of E-glass strength with acrylic's enhanced durability makes it ideal for harsh environments

Applications

- Thermal Insulation (Outer layers for furnace, boiler, and exhaust system jackets, as well as removable insulation covers for pipes and valves)

- Fire & Spark Protection (Welding blankets, fire blankets, curtains, and heat shields to prevent fire spread during hot work)

- Protective Covers (Covering machinery, drapes for high-heat areas, and containment for hot components

- Expansion Joints (Accommodating thermal movement in industrial structures and piping)

- Conveyor Belts (In food processing due to non-stick, heat-resistant properties)

- Acoustic Facing

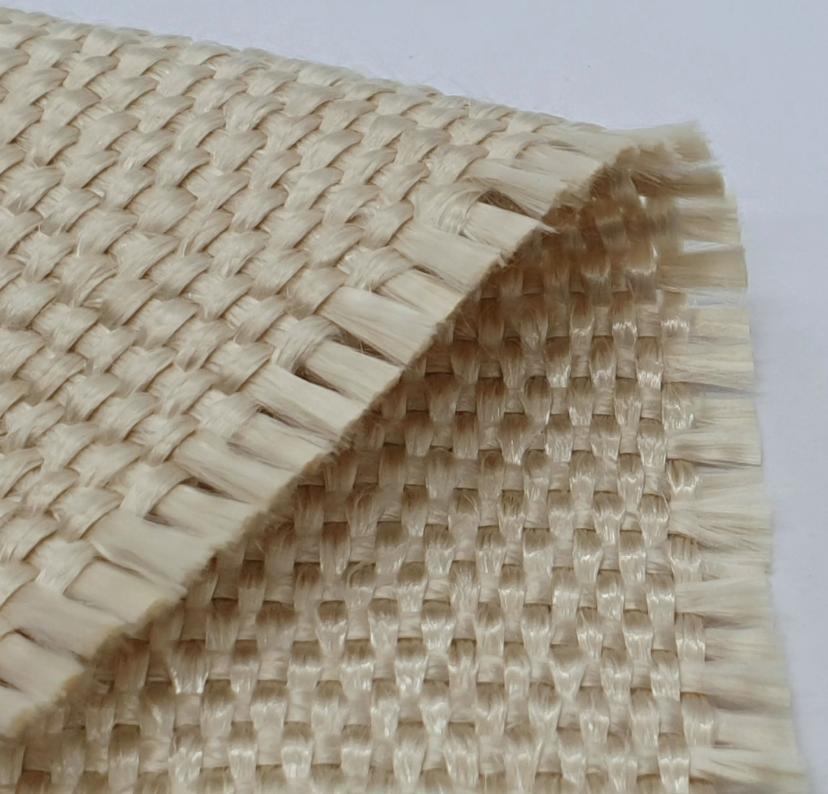

Loomstate

E-Glass Loomstate (loom-finished fiberglass) is a strong, flexible, non-combustible woven fabric used as a base for composites, thermal insulation, fire protection.

Curtains, Blankets, and structural reinforcement, especially in marine, construction, and industrial settings where heat resistance and durability are needed before coatings are applied.

It’s plain weave structure offers uniform strength and is ideal for laminating with resins (like epoxy for boats) or coating with PTFE, silicone, or foil for specialized applications

Applications

- Composites & Laminates (Reinforces structures like boat hulls, canoes, and other fiberglass parts, providing strength and impact resistance)

- Thermal Insulation (Used for high-temperature pipe wraps, furnace linings, and industrial insulation jackets, often treated for extra heat resistance)

- Fire Protection (Made into welding blankets, fire curtains, and heat shields due to its non-combustible nature and ability to withstand high temperatures (up to 550-600°C))

- Protective Coatings (Serves as a substrate for PTFE, silicone, or aluminum foil coatings, creating durable, chemical-resistant materials)

- Construction (Provides support and reinforcement in various building materials)

Heat Treated Fabric

Heat-treated E-glass fabric, with its organic sizing burned off, is used for high-temperature insulation, thermal barriers, and personal protective equipment like welding blankets, curtains, and fireproof materials.

Offering excellent heat/flame resistance for industrial applications where smoke is a concern, such as furnace insulation, expansion joints, and gaskets

- Welding & Fire Protection (Welding blankets, fire curtains, and firewalls to protect against sparks, heat, and flames)

- Industrial Insulation (Pipe & furnace insulation, thermal reflectors, and machinery covers due to its resistance to extreme heat (up to 550-700°C))

- Protective Gear (Personal protective equipment (PPE) like aprons, cuffs, and suits for workers in high-heat environments)

- Expansion Joints (Used in compensators and expansion joints in industrial systems

- Gaskets (High-temperature gaskets for sealing applications.

- Thermal Covers - Exhaust, Muffler, Turbo jackets etc.

- Smoke-Free: Removes organic sizing, preventing smoke during initial use.

- Improved Performance: Offers better abrasion resistance and direct flame resistance after treatment.

- Versatility: Can be further coated (e.g., with silicone or vermiculite) for enhanced properties like water resistance or chemical stability

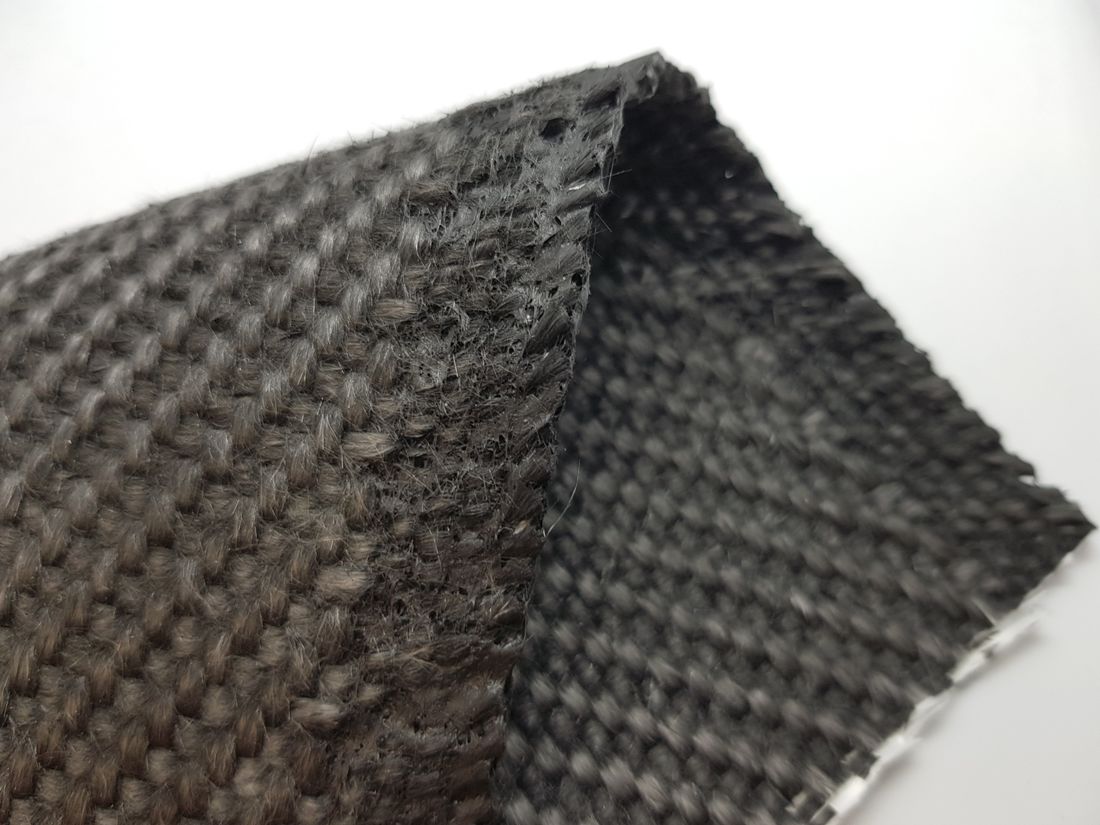

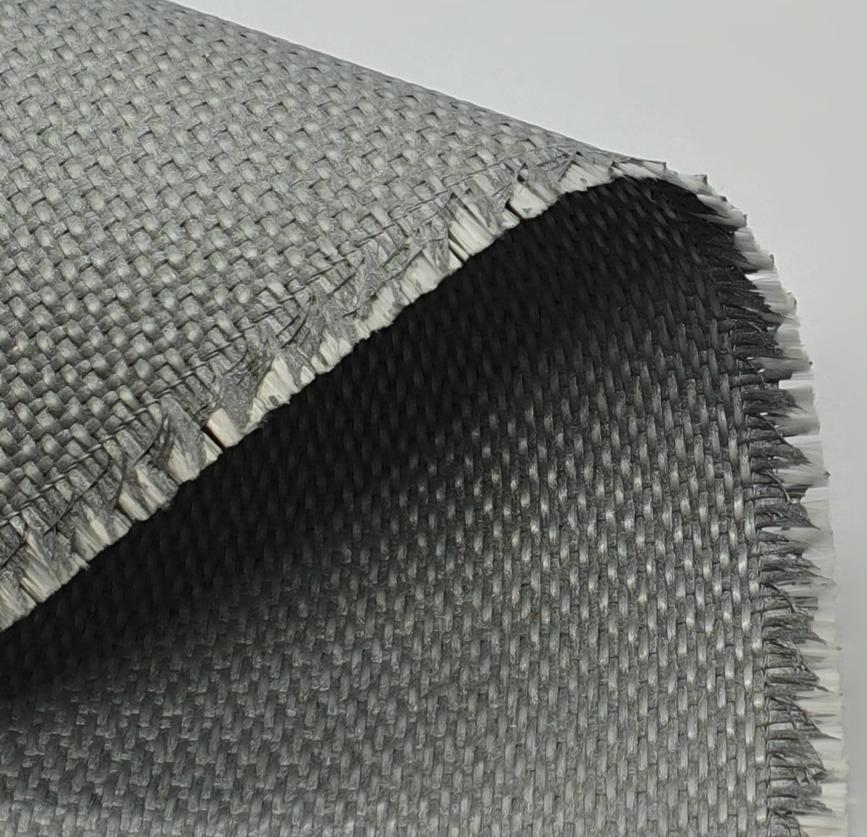

Graphite E-Glass fabric

Graphite E-Glass fabric combines the strength of E-glass with graphite's properties to create high-temperature, fire-resistant material.

Used for thermal insulation, heat shielding, and protective barriers, used in welding blankets, furnace insulation, fire curtains, industrial seals, and protective clothing.

Offering enhanced abrasion resistance and heat reflection for demanding industrial and aerospace applications

Applications

- Thermal & Fire Protection: Acting as protective barriers against molten metal, sparks, and intense heat in foundries, welding shops, and steel factories.

- Welding/Foundry: Protects against molten metal splatter, sparks, and intense heat in welding and casting.

- Insulation: Used for removable pads, furnace linings, pipe insulation, and fireproof barriers.

- Curtains & Blankets: Creates fireproof and heat-resistant curtains for industrial settings and emergency blankets.

Industrial & Automotive

- Heat Shields: Shields components in high-heat industries like aerospace and automotive.

- Seals & Gaskets: Forms high-temperature seals, compensators, and airtight barriers.

- Protective Wear: Makes heat-resistant clothing, gloves, and aprons for workers.

| Darco Stock Code | Description |

| DEF2650GP

| DEF2650GP is a heavy weight woven texturized fiberglass fabric coated with a specially formulated graphite and polyurethane solution which provides high temperature and abrasion resistance properties for the manufacturer of gaskets, flexible expansion joints, removable jackets and other types of fire control systems. Rated to 700°C Size: 1000mm x 2.5mm x 50m Weight: 2650g/m² |

| DEF5600BG/BS | (INDENT ONLY - M.O.Q of 50m and lead time of 3 months) DEF5600BG/BS is a super heavy weight, woven fibreglass fabric, coated with specially formulated tough abrasion resistant graphite-based impregnation (Unlike usual graphite coated fabrics) Rated to 700°C Size: 1000mm x 2.5mm x 50m - |

Dip Coated E Glass Fabric

Dip-coated E-glass fabric, typically treated with silicone, polyurethane, or acrylic, is used for

high-temperature insulation, fire protection, and industrial sealing. It acts as welding curtains, flexible expansion joints, protective equipment, and specialized covers due to its high heat resistance, durability, and chemical resistance.

This Fiberglass fabric is non-asbestos products used for both thermal and electrical insulation in applications including heat shields, welding, stress relieving, removable insulation covers, gasket products, fire blankets, fire curtains, expansion joints and flue ducts.

Applications

- Thermal Insulation: Used for machinery jackets, piping covers, and exhaust insulation.

- Fire & Safety Protection: Manufactured into fire blankets, welding curtains, and splash protection curtains.

- Industrial Seals: Used in flexible compensators and gaskets in piping systems.

- Protective Covers: Applied as protective clothing, removable insulation blankets, and covers for industrial machinery to resist abrasion and chemicals.

The dip-coating process (e.g., with silicone) enhances the base E-glass, ensuring the material is resistant to water, weather, UV, and aging while minimizing fraying and shedding.

| Darco Stock Code | Description |

| DEF450A/1500 | (INDENT ONLY) E Glass Fabric White Acrylic Coated Weave Set The A finish is Alkaline a resistant co polymer finish that also weave sets the flexible fabric After a 28-day immersion of 5% Na OH solution, the average retention rate for tensile fracture strength is greater than 70%. Continuous use to 550oC Size: 1500mm x 0.5mm x 50m Weight: 450g/m² |

| DEF490RW/P/1520

| E Glass Fabric Rewettable - Plain Weave Adhesion - Bonds firmly to fiberglass, calcium silicate, mineral wool, urethane and asbestos. In-combustibility Material is completely incombustible and meets all the requirements for Class 1 Sheathing materials. Contour ability this fabric has been specifically designed to contour around tees and elbows uniformly and evenly. Continuous use to 550oC Size: 1520mm x 0.4mm x 46m Weight: 480g/m² |

| DEF530RW/P/1500 is an E Glass Rewettable fabric, Plain Weave, pre-pasted with adhesive and needs only to be dipped in water to soften and reactivate adhesion. Adhesion - Bonds firmly to fiberglass, calcium silicate, mineral wool, urethane and asbestos. Incombustibility Material is completely incombustible and meets all the requirements for Class 1 Sheathing materials. Contour ability this fabric has been specifically designed to contour around tees and elbows uniformly and evenly. Continuous use to 550oC Size: 1500mm x 038mm x 50m |

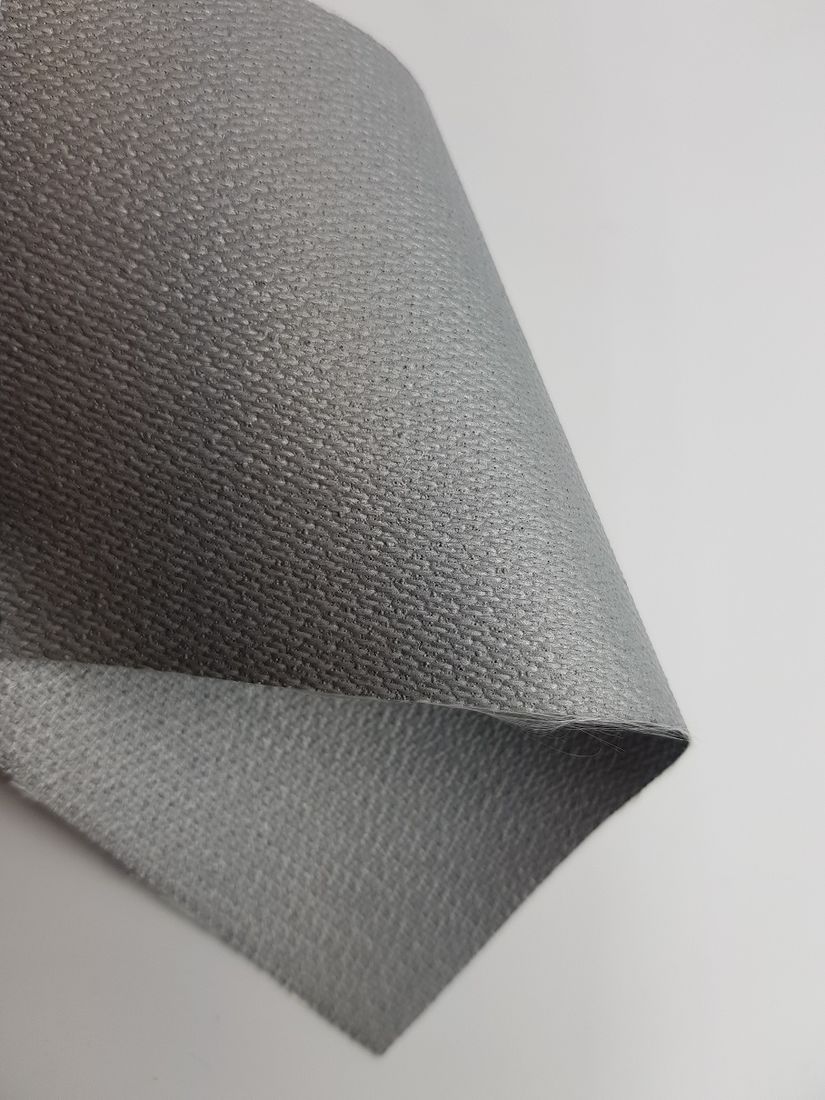

Vermiculite Coated E Glass Fabric

Vermiculite-coated E-glass fabric is a high-temperature resistant textile used for thermal insulation, fire protection, and heat shielding in industrial environments up to 1000°C+.

The coating enhances durability, improves abrasion resistance, and reduces fraying.

It is primarily used for welding blankets, fire curtains, furnace curtains, expansion joints, and pipe insulation in the, metallurgy, and manufacturing sectors.

Applications

- Welding & Fire Protection: Used as welding blankets, fire blankets, and fire-resistant curtains to protect personnel and equipment from molten metal sparks and direct flame.

- Thermal Insulation: Used as removable insulation jackets for pipes, valves, boilers, and furnaces to minimize heat loss.

- Heat Shields & Gaskets: Provides thermal shielding for sensitive components and forms gaskets/seals for industrial ovens and high-temperature equipment.

- Expansion Joints: Used in flexible expansion joints for duct work and high-temperature machinery.

- Industrial Protection: Utilized in the aerospace and automotive industries for insulation and fire protection, as well as in foundries for shielding.

Performance Benefits

- High Temperature & Fire Resistance: The inorganic vermiculite coating provides excellent thermal protection and does not smoke or melt at high temperatures.

- Durability & Handling: The coating reduces fraying, making it easier to cut and sew, and improves resistance to abrasion.

- Safety: It acts as an asbestos-free alternative for high-heat applications

| Darco Stock Code | Description |

| DEF916V/1570 | E Glass Fabric Vermiculite Coated - Premium, Tight weave Continuous up to 550ºC Size: 1570mm x 0.9mm x 25m Weight: 916g/m² |

| E Glass Fabric Vermiculite Coated BLACK This coating provides short temperature resistance of 1000°C and increased continuous temperature resistance temperature up to 800°C Size: 1520mm x 1.8mm x 25m Weight: 1250g/m² | |

| DEF1270V/WR | E Glass Fabric Vermiculite Coated Wire Reinforced Withstands temperature extremes of up to 800°C, no significant deterioration in flexibility or strength, without smoke/fumes release when catches fire. Size: 1000mm x 1.4mm x 50m |

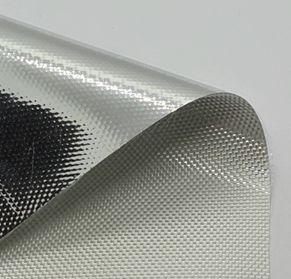

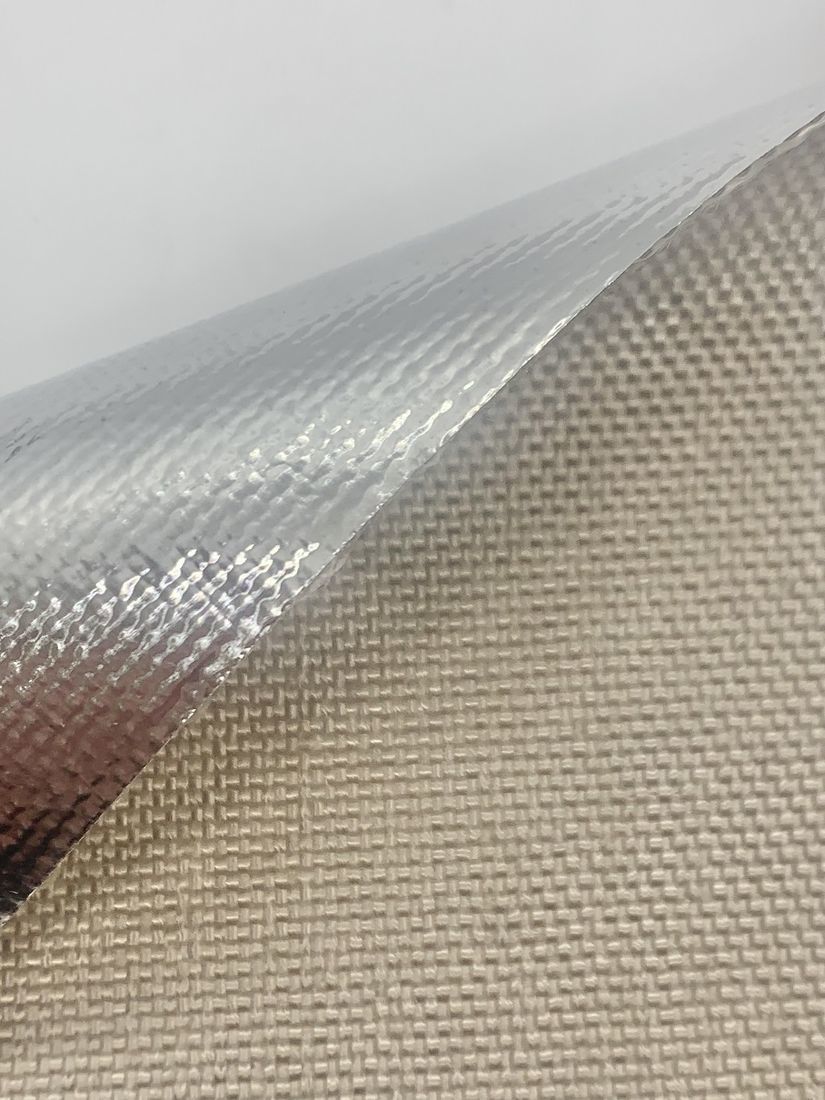

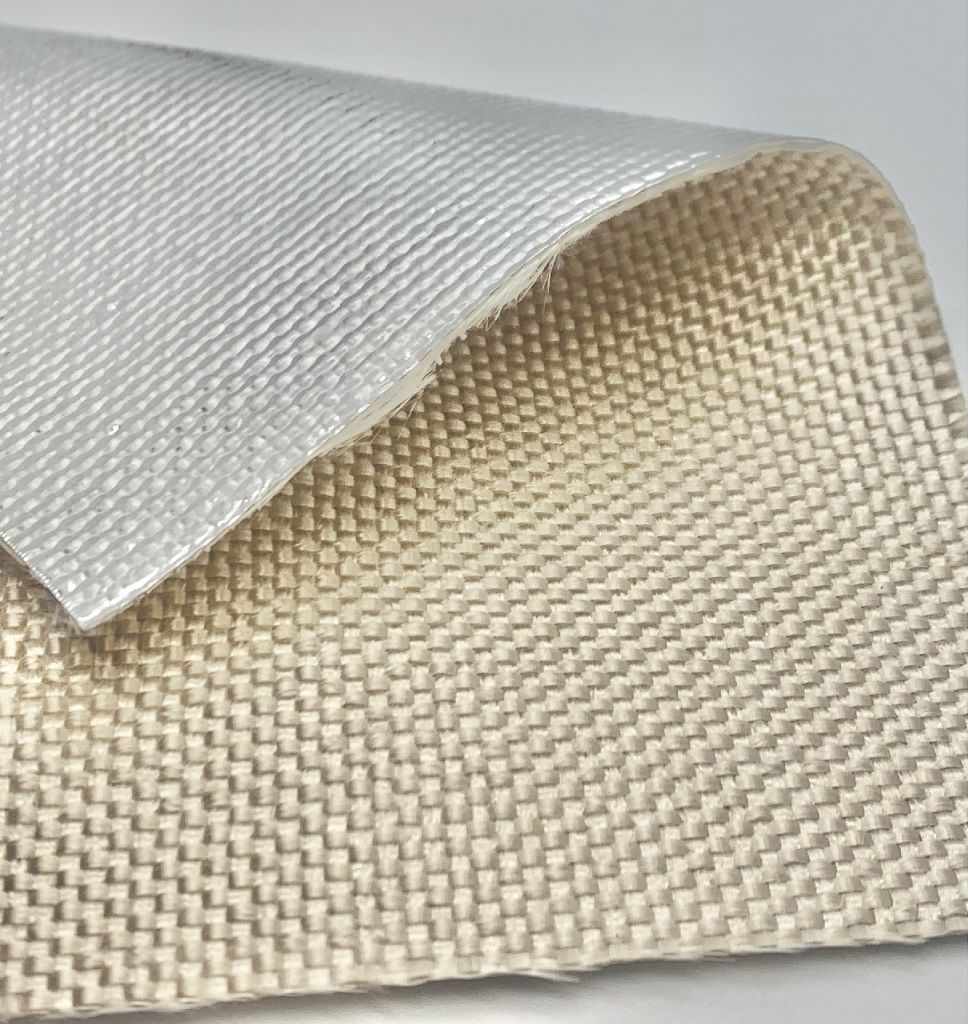

Aluminium Foil Faced Fabrics

Aluminium foil-faced E-glass coated fabrics are composite materials combining reflective, heat-resistant, and flame-retardant properties, designed for high-temperature insulation, radiant heat shields, and protective covering.

These materials are heavily used in industrial, construction, and safety sectors to protect personnel and equipment from heat, sparks, and chemical hazards.

These fabrics provide good properties of flexibility, durability, radiant heat and light reflection as well as vapor protection.

Applications

- Industrial Heat Protection & Insulation: Used for welding blankets, fire curtains, safety clothing, and splash guards for molten metal or chemicals.

- Pipe and Duct Lagging: Provides thermal insulation and vapor barriers for HVAC systems, steam pipelines, and oil transportation lines.

- Expansion Joints & Flexible Connectors: Used in industrial, power generation, and chemical environments to handle thermal expansion and vibration.

- Removable Insulation Jackets: Ideal for covering turbines, valves, and boilers to reduce energy loss.

- Construction & Building: Used for vapor barriers under roof decking, in walls, or in floor heating, offering both radiant heat reflection and moisture resistance.

- Packing Material: Protects large equipment from environmental damage during shipping.

It's the ideal fabric used for cold insulation, reflective work wear, pipe insulation, insulation covers and mattresses, hoses, automotive bellows and heat shields.

| Darco Stock Code | Description |

| E Glass Fabric Aluminium & Polyester (Mylar) Laminated Size: 1500mm x 0.43mm x 50m Weight: 450g/m² | |

| E Glass Fabric Heat Treated Aluminium Foil Laminated 22µ Foil Fibreglass fabric woven from high quality texturized yarn and then passed through a high temperature oven in order to burn off the sizing and other organic elements in the cloth and then laminated with 22-micron thick aluminium foil on one side. This fabric provides good properties of flexibility, durability, radiant heat and light reflection. DEF640HTAL/1500 has high temperature adhesive rated to 250ºC Application Used for thermal insulation jackets, welding blankets, smoke and fire protecting curtains, blinds, cavity wall fire barriers, fire protecting work wear, pipe and furnace insulation. Size: 1520mm x 0.75mm x 50m Weight: 640g/m² | |

| DEF650AL/SW/1500

| E Glass Fabric Aluminium Foil Laminated 18µ Foil Square Weave Size: 1500mm x 0.8mm x 50m Weight: 650g/m² |

| E Glass Fabric Aluminium Foil Laminated Fire with Retardant Polyester film coating on one side for extra liquid spill and vapor barrier protection. Also used for radiant heat and thermal insulation and has high temperature adhesive rated to 250ºC. N.B. Similar to DEF640HTAL-1500 but with additional polyester film facing for a more durable foil surface, that is more crease and crack resistant, and provides for vapour and oils barrier. Application Used for thermal insulation jackets, welding blankets, smoke and fire protecting curtains, blinds, cavity wall fire barriers, fire protecting work wear, pipe and furnace insulation. Size: 1500mm x 0.8mm x 50m Weight: 650g/m² | |

| DEF650AL/SW/1500 | (INDENT ONLY - only and available upon request with international shipping lead times) E Glass Fabric Aluminium Foil Laminated 18µ Foil Square Weave Application Used for thermal insulation jackets, welding blankets, smoke and fire protecting curtains, blinds, cavity wall fire barriers, fire protecting work wear, pipe and furnace insulation. Size: 1500mm x 0.63mm x 50m Weight: 650g/m² |

| E Glass Fabric Aluminium Foil Laminated - MED Cert Loomstate E Glass Fabric providing high radiant heat reflection, vapor retarder and barrier to water and oil. Also used for radiant heat and thermal insulation. DEF660AL/HKO has high temperature adhesive rated to 250ºC. This product is a HKO MED Certified product: TG 660/9A Application Used for thermal insulation jackets, welding blankets, smoke and fire protecting curtains, blinds, cavity wall fire barriers, fire protecting work wear, pipe and furnace insulation. Size: 1000mm x 0.78mm x 50m Weight: 660g/m | |

| DEF663HTAL/1500 | E Glass Fabric Heat Treated Aluminium Foil Laminated - US Mil-Spec Mil Spec Alpha Engineered Composites USA E Glass fabric that is laminated with a special higher temperature adhesive to Aluminium foil. To provide a vapour retarder and a barrier to water and oil. Also used for radiant heat and thermal insulation. The product has been specifically designed as a flange shield material. Since it must meet US Coast Guard Specification, a very low percentage of adhesive is used. Material should be tested prior to use for commercial applications. Meets the requirements of Coast Guard Specification 164.009 for fire retardant material and is included in Military Specification MIL-C-20079G, Type 1, Class 10. Also meets Military Specification MIL-I-24244B and NRC Guide 1.36 Size: 1520mm x 0.66mm x 45.72m Weight: 663g/m |

| DEF1000HTAL | E Glass Fabric Heat Treated Aluminium Foil Laminated CARAMELISED is tan in colour and is loomstate that has been heat cleaned to lower volatiles. Application Heat shields, welding, stress relieving, removable insulation covers, gaskets, fire blankets, fire curtains, expansion joints, and flue ducts. Size: 1000mm x 1.8mm x 50m Weight: 1000g/m |

| DEF1000AL | E Glass Fabric, White Loomstate 25µ Aluminium Foil Laminate Application Heat shields, welding, stress relieving, removable insulation covers, gaskets, fire blankets, fire curtains, expansion joints, and flue ducts. Size: 1000mm x 1.5mm x 50m Weight: 1050g/m |

Acrylic/Neoprene

Acrylic/Neoprene coated E-glass fabric is a high-performance industrial material that combines the high-temperature resistance of E-glass fiber with the chemical, weather, and abrasion resistance of neoprene and acrylic coatings

. It is used extensively as a protective, heat-resistant barrier in industries such as manufacturing, shipbuilding, power generation, and automotive.

No difference from fiberglass loomstate, but especially for the application where smoke is not allowed.

Applications

Fire and Welding Protection

- Welding Blankets and Curtains: Used to protect personnel, equipment, and floors from sparks, spatter, and slag during hot work processing.

- Fire Curtains and Smoke Barriers: Acts as a barrier in fire doors, smoke seals, and fire curtains.

- Fireproof Clothing: Used in the fabrication of protective heat-retardant gloves and suits.

Thermal Insulation

- Removable Insulation Jackets: Used as the outer layer for insulation machinery jackets (boilers, furnaces, exhaust systems).

- Pipe Insulation and Wrapping: Ideal for covering and repairing insulation on pipes, vessels, and tanks.

- Valve and Flange Jackets: Provides protection for valves and joints, reducing heat loss.

Industrial Sealing and Expansion

- Flexible Expansion Joints: Utilized as a flexible compensator in duct work to handle thermal movement, vibrations, and expansion in industrial systems.

- Flexible Duct Connectors: Used in HVAC and ducting systems for sealing and, because of the coating, resisting aging and moisture.

Protective Covers and Environmental Resistance

- Outdoor Equipment Covers: Due to the neoprene coating's excellent resistance to weathering, UV rays, and ozone, it is used for outdoor covers, bellows, and protective barriers.

- Anti-Corrosion Covers: Protects against water, oil, and chemical splashes in harsh industrial environments.

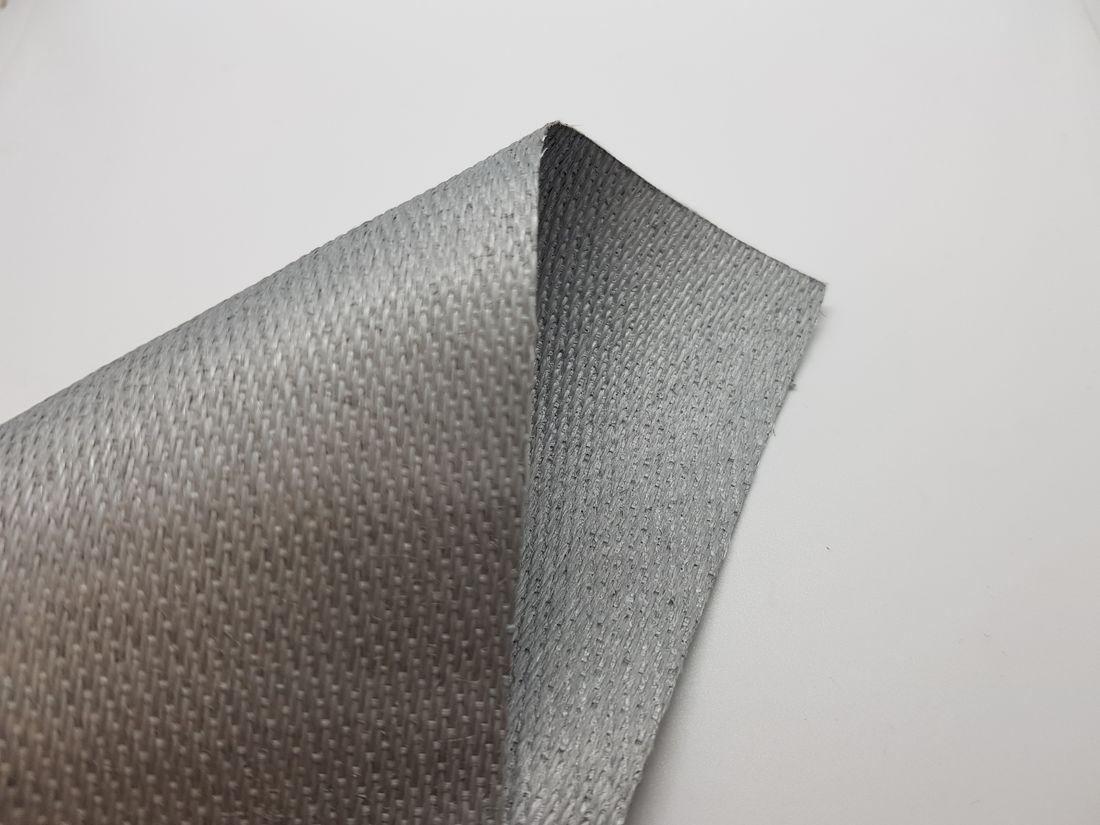

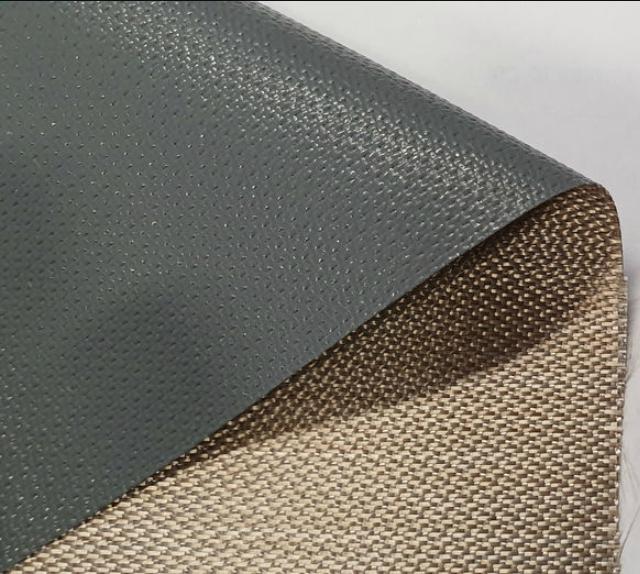

Polyurethane

Polyurethane (PU) coated E-glass fabric is a high-performance industrial material designed for thermal insulation, fire protection, and abrasion resistance.

It is commonly used for welding blankets, safety curtains, expansion joints, pipe wrapping.

Also used for removable insulation jackets to protect against molten metal splashes, sparks, and high-temperature environments.

Applications

- Thermal Insulation & Fire Protection: Used in industrial furnaces, boilers, and exhaust systems as insulation blankets, protective covers, and curtains due to its ability to handle high temperatures (approx. 500°C–600°C).

- Welding & Safety Equipment: Fabricated into welding blankets, curtains, and aprons to protect personnel and equipment from sparks, flames, and molten metal splatter.

- Expansion Joints & Seals: Used in construction and power plants to create flexible, non-metallic compensators, seals, and gaskets that manage thermal expansion.

- Industrial Covering: Utilized as pipe wraps, duct work insulation, air-handling blankets, and protective covers for machinery.

- Conveyor Components: Employed in specialized conveyor belts in the packaging industry due to its non-stick and durable characteristics

- Good Anti slip properties and fray proof

Available in different shades

| Darco Stock Code | Description |

| DEF455P/PU2 | E Glass Fabric Premium Polyurethane Coated 2 sides Grey For 60+ minutes fire barrier FRL -/60/- Size: 1000mm x 0.4mm x 50m Weight: 490g/m² |

| DEF460PU2

| E Glass Fabric Premium Polyurethane Coated 2 sides Grey For 60+ minutes fire barrier FRL -/60/- Size: 1000mm x 0.43mm x 50m Weight: 460g/m² |

| E Glass Fabric Polyurethane Coated 1 side, wire reinforced Grey Flame-retardant finish, resistant up to a continuous temperature of approx. 700°C, short exposure up to approx. 750°C. Size: 1520mm x 0.6mm x 25m Weight: 690g/m² | |

| DEF780P2/WR/1200 | E Glass Fabric Polyurethane Coated 2 sided, wire reinforced Grey For 120+ minutes fire barrier FRL -/120/- Maximum application temperature 500°C, shortly up to 600°C Size: 1200mm x 0.7mm x 50m |

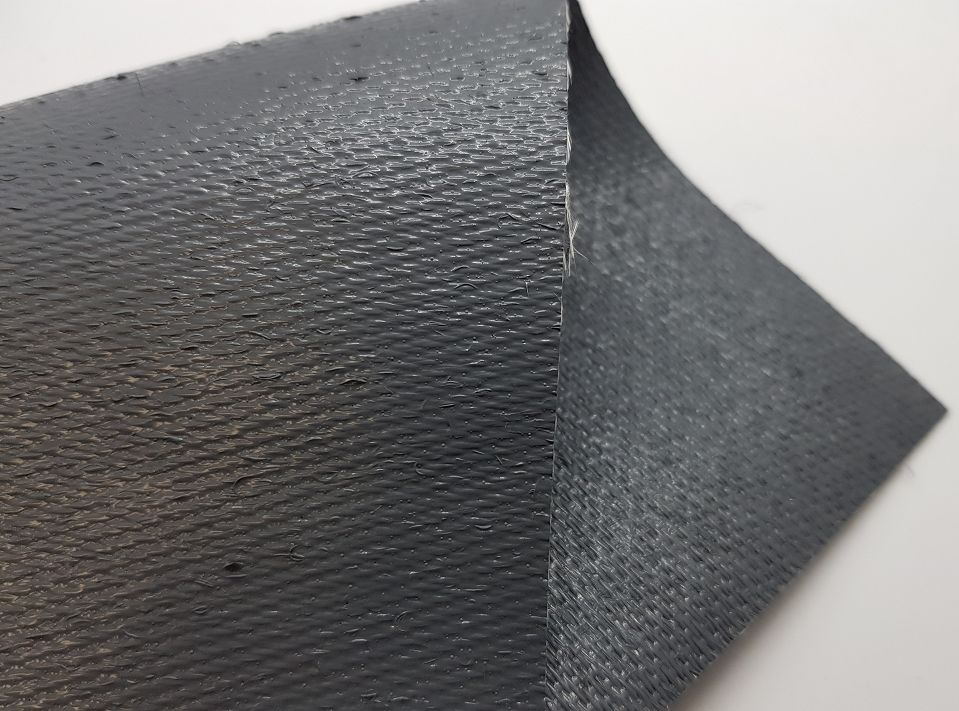

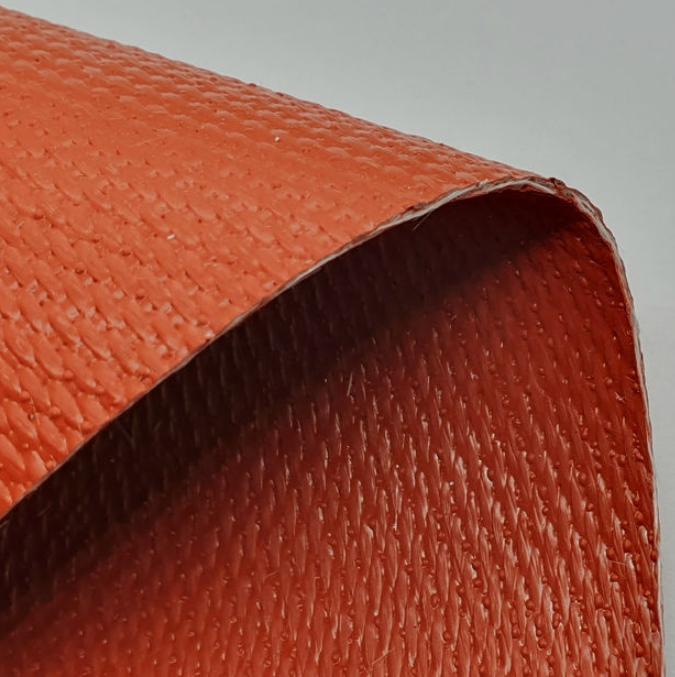

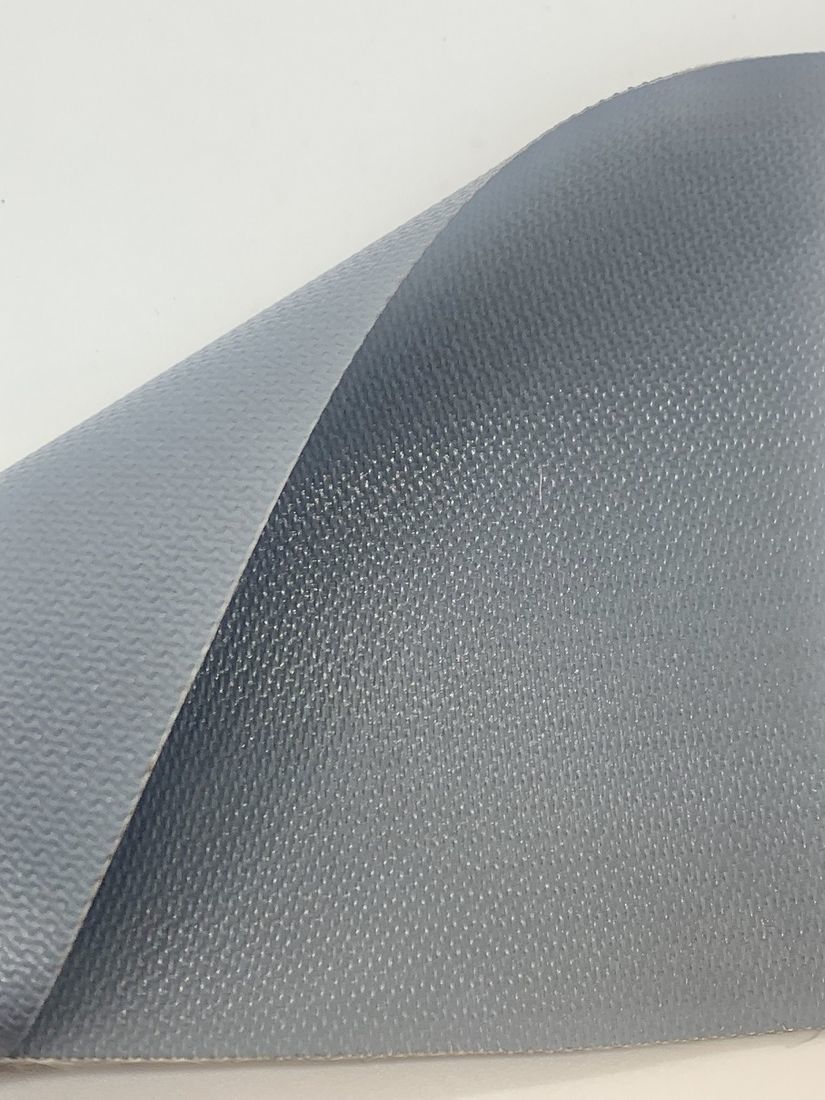

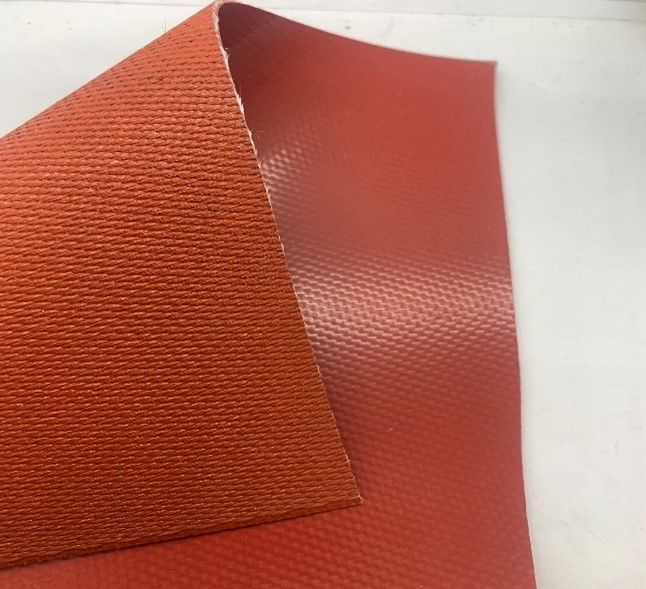

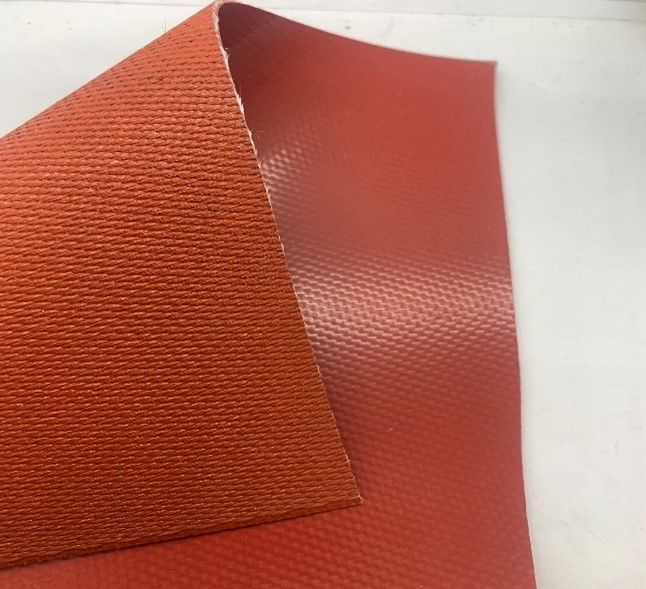

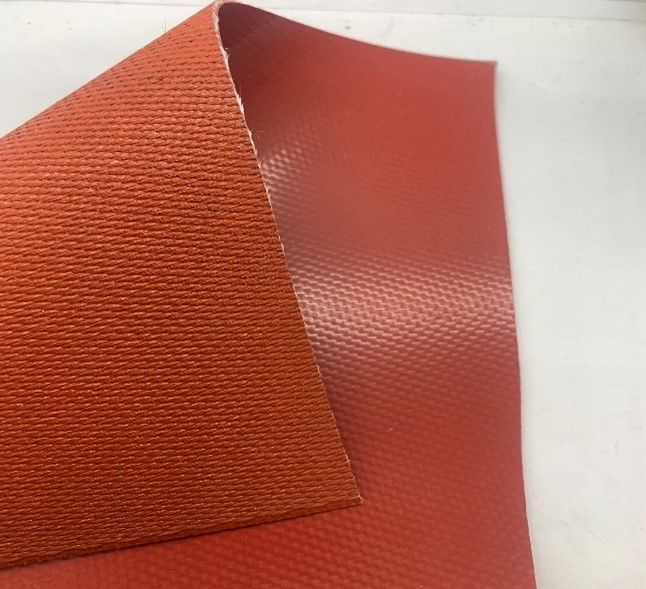

Silicone Coated

Silicone coated fabric, typically made by applying silicone rubber to a fiberglass base, is primarily used for high-temperature insulation, fire protection, and environmental sealing.

It is heavily used for welding blankets, expansion joints, protective covers, conveyor belts, and waterproof outdoor gear.

This durable material provides resistance to chemicals, UV light, and heat up to 260°C

Available in Grey, Red, Black, and White.

Applications

- Industrial Insulation and Protection: Used for removable insulation jackets, thermal insulation barriers, pipe wrap, and bellows.

- Fire and Safety: Ideal for welding curtains, fire barriers, and blankets designed to resist molten metal splash and flames.

- Sealing and Gasketing: Used to create flexible seals, gaskets, and gaskets in machinery, particularly in high-temperature environments.

- Manufacturing and Material Handling: Used as conveyor belts, heat-resistant, or non-stick surfaces in manufacturing processes.

- Outdoor and Technical Textiles: Used in tents, awnings, and bags due to its waterproofing, lightweight, and UV-resistant properties.

- Medical and Specialized Sectors: Used in medical devices due to its durability and non-toxic properties.

Key Components of a Mil Cert

- Chemical Analysis: The exact percentage of elements (e.g., carbon, nickel, chromium) in the alloy.

- Mechanical Properties: Results of tests for tensile strength, yield strength, hardness, and elongation.

- Heat Number (Batch ID): A unique identifier for the specific melt or batch, allowing for full traceability.

- Applicable Standards: Confirmation that the material meets specific, industry-standard requirements, such as ASTM or AISI.

- Manufacturer Information: Details of the mill that produced the material.

Why Mil Certs Matter

- Safety & Compliance: They verify that materials used in construction, pipelines, or machinery meet safety standards, preventing failures.

- Traceability: The heat number allows buyers to trace the material back to its original production batch.

- Biocompatibility: In industries like body jewelry or medical, they confirm the material is safe for long-term wear

Silicone Coated - GREY

| Darco Stock Code | Description |

| DEF570GLS2/1500/V | E Glass Fabric Silicone Coated 2 sides Wire Reinforced Grey MED marine certified Certificate No. 164.112/1121/WCL MED0310QA. Valid to 3 Nov 2024 (Doc 310QA Valmiera Glass) Size: 1500mm x 0.5mm x 50m Weight: 570g/m² |

| DEF590P/GLS2/1500 |

E Glass Fabric Silicone Coated 2 sides Wire Reinforced Grey Size: 1500mm x 0.45mm x 50m Weight: 590g/m² |

| DEF595GS2/1524/A

| E Glass Fabric Silicone Coated 2 sides Wire Reinforced Grey ALPHA Mil Cert MED marine certified Certificate No. 164.112/1121/WCL MED0310QA. Valid to 3 Nov 2024 (Doc 310QA Valmiera Glass) Size: 1524mm x 0.45mm x 50m Weight: 595g/m² |

| DEF1060GLS2/WR/1500 | E Glass Fabric Silicone Coated 2 sides Wire Reinforced Grey Size: 1500mm x 0.9mm x 25m Weight: 1060g/m² |

| DEF1150GLS2/1520 | E Glass Fabric Silicone Coated 2 sides Wire Reinforced Grey Size: 1520mm x 0.94mm x 25m |

Silicone Coated - RED

| Darco Stock Code | Description |

| DEF590P/RLS2/1500

| E Glass Fabric Silicone Coated 2 sides Iron Red Size: 1500mm x 0.45mm x 50m Weight: 590g/m² |

| DEF1150RLS2/1520

| E Glass Fabric Silicone Coated 2 sides Iron Red Size: 1520mm x 0.90mm x 25m Weight: 1120g/m² |

| DEF1800RLS2

| E Glass Fabric Silicone Coated 2 sides Red Size: 1000mm x 1.60mm x 25m Weight: 1800g/m² |

| DEF1910RLS1

| E Glass Fabric Silicone Coated 1 side Red Size: 1000mm x 1.98mm x 25m Weight: 1910g/m² |

| DEF3500RLS2/Y

| E Glass Fabric Silicone Coated 2 sides Iron Red Size: 1000mm x 2.4mm x 25m Weight: 3500g/m² |

Silicone Coated - RED - Various Widths

| Darco Stock Code | Description |

| DEF1600RLS2/270  | E Glass Fabric Silicone Coated 2 sides Calendared Red Size: 270mm x 1.30mm x 50m Weight: 1800g/m² |

| DEF1600RLS2/480  | E Glass Fabric Silicone Coated 2 sides Calendered Red Size: 480mm x 1.30mm x 50m Weight: 1800g/m² |

| DEF1600RLS2/570  | E Glass Fabric Silicone Coated 2 sides Calendered Red Size: 570mm x 1.30mm x 50m Weight: 1800g/m² |

| DEF1900RLS2/270

| E Glass Fabric Silicone Coated 2 sides Calendered Red Size: 270mm x 1.30mm x 50m Weight: 1900g/m² |

| DEF1900RLS2/480

| E Glass Fabric Silicone Coated 2 sides Calendered Red Size: 480mm x 1.30mm x 50m Weight: 1900g/m² |

| DEF1900RLS2/570

| E Glass Fabric Silicone Coated 2 sides Calendered Red Size: 570mm x 1.30mm x 50m |

Silicone Coated - BLACK

| Darco Stock Code | Description |

| DEF960BLS1/1520 | E Glass Fabric Silicone Coated 1 side Black Size: 1520mm x 0.90mm x 25m |

Silicone Coated - WHITE

| Darco Stock Code | Description |

|

DEF580WS2

| E Glass Fabric Silicone Coated 2 sides White Size: 1000mm x 4.00mm x 22m Weight: 580g/m² |

Teflon Coated Fabric

Teflon PTFE / Fluorocarbon coating provides the best chemical resistance.

Teflon-coated fabric is primarily used

to create durable, water-resistant, and stain-resistant materials for apparel, outdoor gear, and home upholstery.

It acts as an invisible, non-stick, and breathable barrier that repels water, oil, and dirt.

The Teflon coating PTFE works by protecting fibers without affecting the feel or breathability of the fabric, facilitating easier cleanup and increasing longevity.

Applications

- Apparel and Workwear: Used on jackets, pants, school uniforms, and workwear to make them stain-resistant, water-repellent, and durable. It allows liquids to bead up and roll off while keeping clothing looking new longer.

- Outdoor Gear and Protective Clothing: Extensively used in tents, backpacks, sleeping bags, and outerwear for hiking, skiing, and camping to protect against moisture and dirt.

- Home Textiles and Upholstery: Applied to furniture, curtains, cushions, and tablecloths to make them easy to clean and stain-resistant.

- Industrial and Technical Applications: Used in high-temperature environments, such as for machine covers, conveyor belts, insulation, and in the automotive or aerospace industries.

- Medical and Specialized Fabrics: Used in protective apparel and products that require consistent, high-performance protection against liquids.

| Darco Stock Code | Description |

| Fibreglass Teflon Coated 1 Side, Premium softer handle Size: 1520mm x 0.42mm x 50m Weight: 580g/m² | |

| E Glass Fabric Teflon Coated 2 side - Premium Grey Size: 1500mm x 0.45mm x 50m Weight: 610g/m² |

SILICA / QUARTZ GLASS FABRIC

Silica Fabric Vermiculite Coated

Silica fabric with a vermiculite coating is used for extreme high-temperature insulation, fire protection, and heat shielding.

Used for as welding blankets, fire curtains, expansion joints, removable insulation jackets for pipes, and high-temperature gaskets.

Industries like metallurgy, power generation, and manufacturing, offering excellent heat resistance (up to 1000°C+) and abrasion resistance.

The vermiculite coating enhances durability and reduces fraying during cutting and sewing, making it a safer, high-performance alternative to asbestos

Applications

- Welding & Fire Protection: Used for welding blankets, curtains, and screens to protect workers and equipment from sparks and intense heat.

- Thermal Insulation: Creates removable insulation for hot pipes, valves, flanges, and industrial equipment (like boilers and furnaces).

- Expansion Joints & Gaskets: Forms flexible seals for duct work, bellows, and pipe joints to accommodate thermal expansion.

- Heat Shields: Protects sensitive components from radiant heat in harsh environments.

- Stress Relief: Used in post-weld heat treatment for thermal insulation.

Benefits of Vermiculite Coating:

- Enhanced Abrasion Resistance: Makes the fabric more durable and easier to cut and sew.

- Improved Temperature Performance: Increases the continuous operating temperature.

- Chemical Inertness: Resists acids and alkalis.

- Safer Alternative: Replaces asbestos in high-temperature applications.

Industries

- Steel & Foundries

- Power Plants

- Oil & Gas

- Aerospace & Automotive (EV Battery fires)

- Shipbuilding

| Darco Stock Code | Description |

| DSF630V/900 | Silica Fabric Vermiculite Coated - FM APPROVED

|

| DSF630V/1524

| Silica Fabric Vermiculite Coated - FM APPROVED, Lower smoke

|

| DSF630AL | Darco DSF630AL is woven by high quality Silica texturized yarn and then pass through an oven with high temperature in order to burn off the sizing and other organic elements in the cloth and then laminated with 18 or 25micron thick aluminium foil on one side. These fabrics provide good properties of flexibility, durability, heat and light reflection.

|

| DSF650V/920R | Silica Fabric Vermiculite Coated on both sides, mainly used above 1000°C (above E glass rating) for all high temperature applications where the need for thermal insulation and/or protection is required.

|

| DSF650V/914W | Silica Fabric Vermiculite Coated on both sides, mainly used above 1000°C (above E glass rating) for all high temperature - Welding Spec.

|

| DSF820GLS2/1500 | Silica Fabric Silicone Coated 2 sides Grey

|

| DSF1150/A/BR | 1150gsm, Silica GOLD Weave-locked Acrylic coated

|

| Darco DSF1150V/920 High Silica cloth represents a modern product generation that meets all stringent requirements as to temperature consistency and environmental health standards. Used in a variety of industrial applications because of its outstanding characteristics, workability in cutting, sewing and resistance to corrosive attack. Moreover, with the outstanding continuous working temperature 1000°C and the soften temperature up to 1700°C Darco high silica cloth could be used in most high temperature working surroundings for thermal insulation and heat protective. Vermiculite coating enhances the high temperature working stability and durable usage.

| |

| DSF1300V/920R | Silica Fabric Vermiculite Coated, 1100°C Welding Spec. This coating provides resistance of 1000oC continuous temperature. Vermiculite coated fiberglass cloths increase the products abrasion resistance and adds to its ability to withstand direct flame, it also provides a dust suppression coating which allows for a safer work environment. |

Pre-Oxidized Carbon Fibre

Pre-oxidized carbon fiber (often from PAN precursor) fabric is used for high-temperature, flame-retardant, and protective applications.

These include protective clothing (firefighters, military), automotive insulation/friction parts (brakes, engine), aerospace components, industrial seals/gaskets.

It also a precursor for full carbon fiber composites, prized for its thermal stability and chemical resistance as a safe asbestos alternative

Applications

- Personal Protective Equipment (PPE): Fire-resistant suits, welding apparel, gloves, blankets, and military combat uniforms.

- Automotive & Transportation: Engine insulation, soundproofing, brake pads, carpets, fuel tank insulation, and high-speed train components.

- Aerospace: Aircraft interiors, heat shields, and protective gear.

- Industrial: High-temperature gaskets, sealing materials, filter media, welding spark protection, and thermal insulation.

- Electronics & Energy: High-temperature cables, circuit boards, battery electrodes, and photovoltaic applications.

- Construction & Home Furnishing: Flame-retardant curtains, insulation, and soundproofing.

- Specialized Uses: As an asbestos replacement in friction materials like brake linings for trains and elevators.

Why it's Used

- High Thermal Stability: Withstands extreme temperatures without melting or shrinking.

- Excellent Flame Retardancy: Non-flammable and doesn't melt, making it ideal for fire protection.

- Chemical Resistance: Resists corrosion from acids and alkalis.

- Asbestos Alternative: A safer, high-performance replacement for hazardous asbestos.

- Precursor Material: Can be carbonized further to produce true carbon fiber for advanced composites.

| Darco Stock Code | Description |

| Darco DPCF516 is made of texturized pre-oxidized carbon fiber yarn, it has good properties such as high temperature resistance to 1000°C, low thermal conductivity coefficient, anti-corrosion, high dust-accommodation and high filterability, moreover it does no harm to the human body and is a good replacement for asbestos products. Soft and comfortable to handle, not itchy, fireproof. Ideal softer, thicker (1.75 mm thick) more insulating alternative to similar price DSF650CV silica fabric (0.6 mm thick) for welding protection and removable insulation covers hot face lining It’s the ideal welding blanket, fire protecting curtain for soft non itchy fabric. |

Ceramic Fibre

Ceramic fibre fabric is used as a high-temperature insulation and protective material, creating furnace linings, heat shields, gaskets, and wraps for extreme heat environments.

Industries like metal processing, power plants, and shipbuilding, as well as for DIY projects like pizza ovens.

Due to its excellent resistance to intense heat (up to 1260°C+) and chemicals, low thermal conductivity, and flexibility

Applications

- Industrial Insulation: Furnace linings, kiln insulation, boiler seals, and hot gas duct linings for steel, aluminum, and chemical plants.

- Protective Gear & Barriers: Welding blankets, heat shields, safety curtains, molten metal splash protection, and pipe/cable wraps.

- Sealing & Gaskets: High-temperature gaskets, expansion joints, and seals for industrial equipment.

- Thermal Management: Thermal insulation layers in electronics, automotive mufflers, and conveyor belts.

- DIY Projects: Insulation for pottery kilns and pizza ovens.

Key Properties

- Extreme Heat Resistance: Withstands continuous temperatures over 1000°C (up to 1260°C or higher with reinforcement).

- Chemical Resistance: Resists acids and alkalis.

- Lightweight & Flexible: Easy to cut, shape, and install, making it versatile.

- Low Thermal Conductivity: Conserves energy by reducing heat loss.

- Reinforcement Options: Often reinforced with stainless steel wire for increased strength or fiberglass for better alkali resistance

| Darco Stock Code | Description |

| Darco DCF3/WR ceramic fibre fabric is a woven fabric made of high-quality ceramic fibre yarns. It can be used for high temperature applications up to 1000°C. The cloth is reinforced with fibreglass filament, and stainless steel wire. It contains a certain amount of binder material which is normally burned at lower temperature and does not affect the insulation property. – Note: The Grams per Sqm for Heat Treated fabric can lose up to 17% of its weight from Organic materials during the treatment. |

Heavy Duty Insertion Rubber

All items with a Darco Stock Code are bulk imported and in stock.

Darco DNR/SBR3 & DNR/SBR6 is a black, superior grade, blended 60 Duro Natural and Synthetic rubber sheet, reinforced with heavy Conveyor Belt Nylon fabric.

The strong Nylon fabric reinforcement gives extremely high tear strength and dimensional stability and making it suitable for heavy duty hanging applications.

Heavy Duty Insertion Rubber is a fabric-reinforced (usually nylon or cotton) rubber sheet designed for

high-strength, tear-resistant sealing and protective applications. It is used for industrial pipe gaskets, flange gaskets, heavy machinery flaps, anti-vibration pads, and protective linings, offering superior durability, dimensional stability, and pressure resistance compared to unreinforced rubber.

Application

- Gasketing & Sealing: Primarily used for flange gaskets on pipes, tanks, and marine applications to prevent leaks of water, air, and some chemicals.

- Industrial Protection: Used as wear-resistant pads, lining for toolboxes, and to cover metal joins or sharp edges.

- Heavy Machinery & Equipment: Ideal for mudguards on vehicles, flaps on agricultural machinery, and protective strips.

- Structural Support: Used as bearing pads in structural applications requiring high load capacity.

- Agriculture & Infrastructure: Used for equine stall dividers, yard barriers, and fencing.

EPDM (Ethylene Propylene Diene Monomer)

Darco DPEPDM3/DPEPDM6 is a black premium grade 70 EPDM rubber sheet, reinforced with a tear resistant Nylon monofilament fabric.

It has high temperature resistance and chemical resistance to acids and alkalis. It is completely UV stabilized making it highly resistant to ozone effects and extreme weather conditions and is ideal for long term outdoor applications.

Premium grade 70 EPDM (Ethylene Propylene Diene Monomer) rubber is a high-performance synthetic elastomer known for its superior resistance to weathering, ozone, UV, and water

With a 70 Shore A durometer (hardness), it provides a firm, durable material suited for demanding sealing, gasket, and outdoor applications, typically operating efficiently in temperatures between -40°C and +120°C.

Applications

Seals and Gaskets: It is extensively used to manufacture gaskets, washers, and O-rings for sealing applications that require resistance to water, steam, and mild chemicals.

Outdoor and Marine Environments: Due to its excellent UV and ozone resistance, it is ideal for outdoor, marine, and aquatic applications, including seaplane components, boat hatch seals, and coastal infrastructure.

Potable Water Applications: Specifically certified grades (such as AS/NZS 4020) are used for seals, gaskets, and liners in contact with drinking water, including potable water pipes and storage tanks.

Construction and Roofing: It is used as a waterproofing membrane for roofs, flashing, and in glazing applications to prevent moisture ingress.

Industrial Linings and Covers: It serves as a lining material for tanks, pipes, and mills to protect against abrasion and chemical corrosion.

Automotive and Transportation: It is used for weather stripping, seals for doors and windows, and other parts exposed to high temperatures and weather, such as hose applications.

Vibration and Sound Damping: Due to its elasticity, it is used for bumpers, pads, and mounts to reduce noise and vibration in machinery.

Reinforced Applications: 70 Duro EPDM with reinforcement (e.g., Nylon insertion) is used for high-strength applications like conveyor skirting, curtains, and heavy-duty gaskets that require high tear resistance.

| Darco Code | Description. |

| DPEPDM3 |

INDENT ONLYPremium EPDM 70 Insertion Rubber, Nylon Monofilament Reinforced Black

|