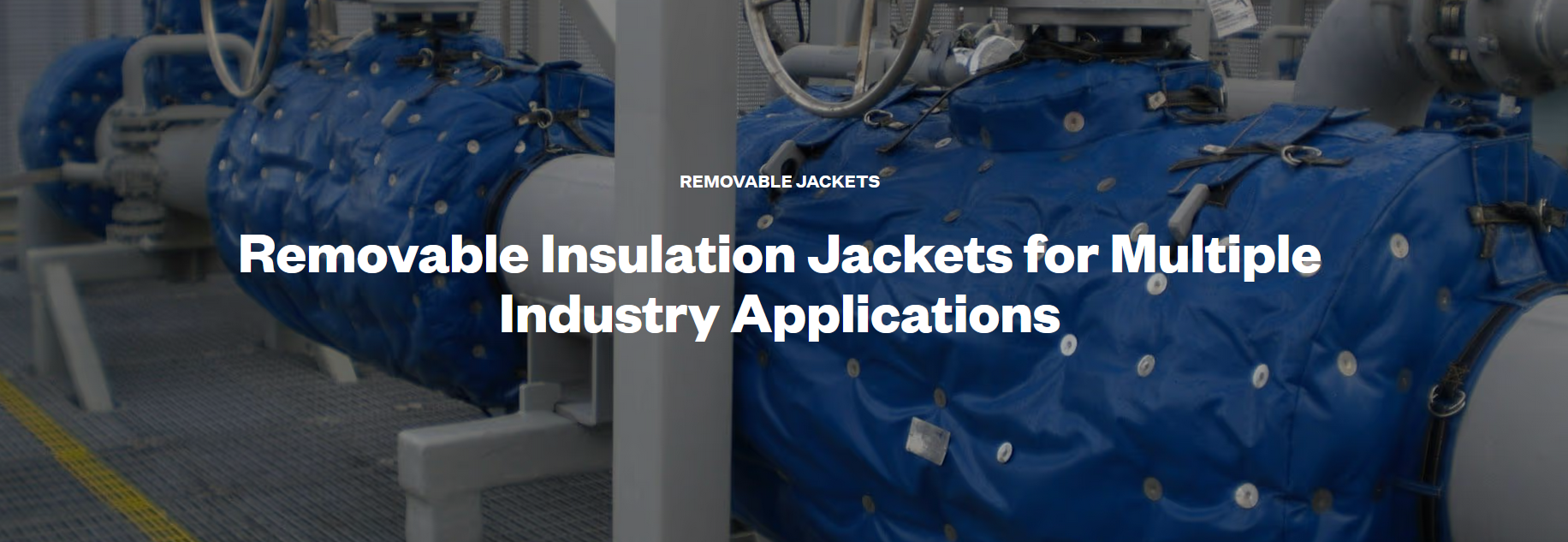

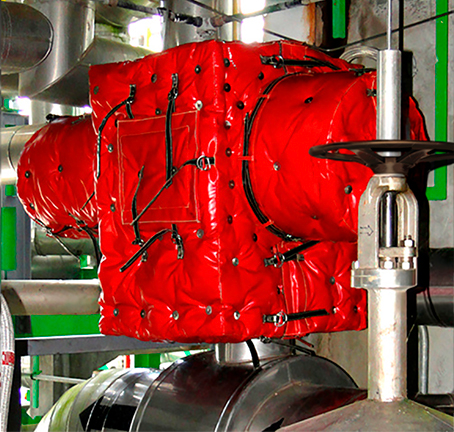

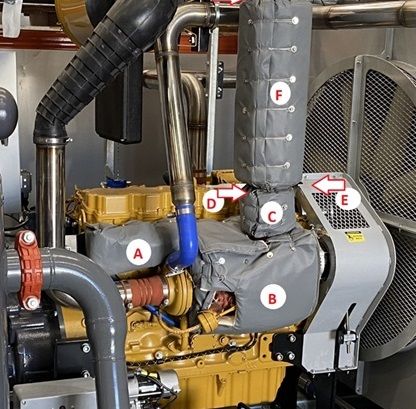

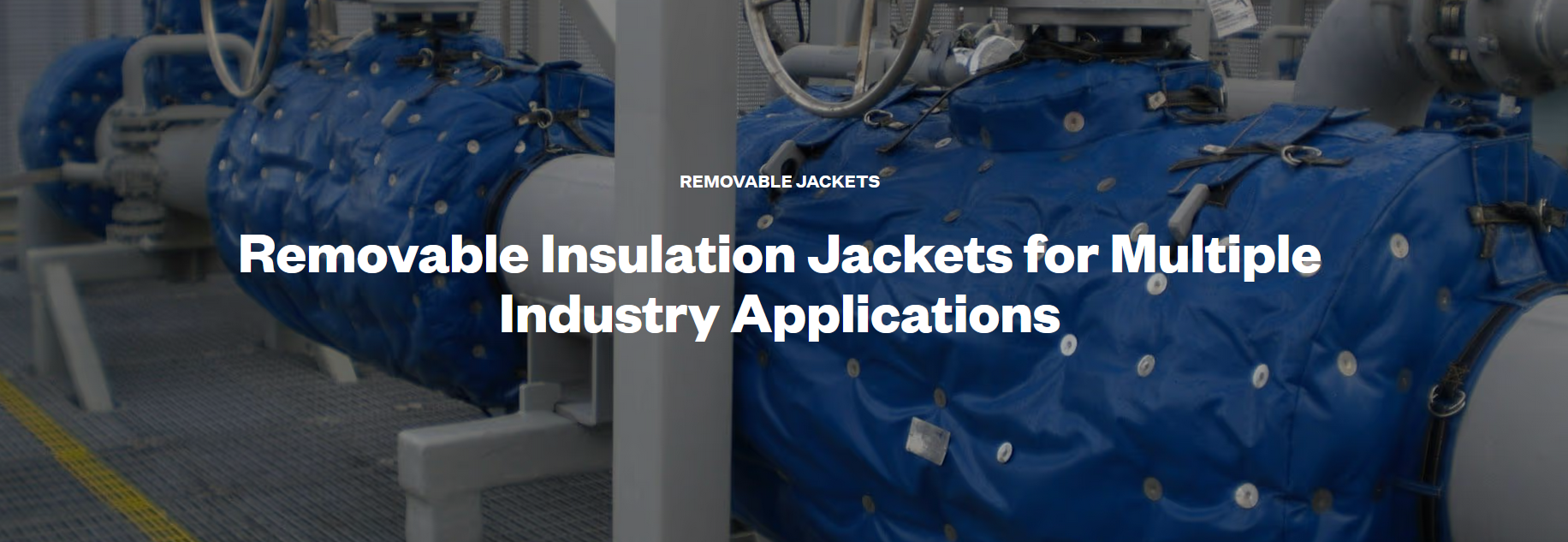

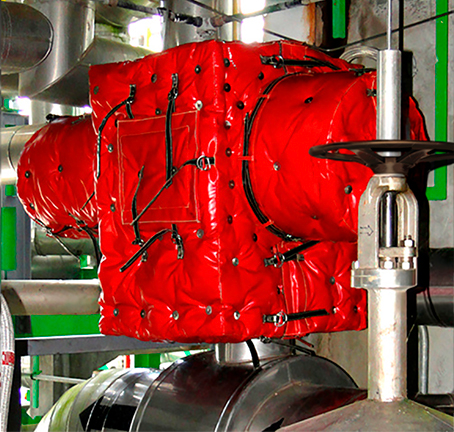

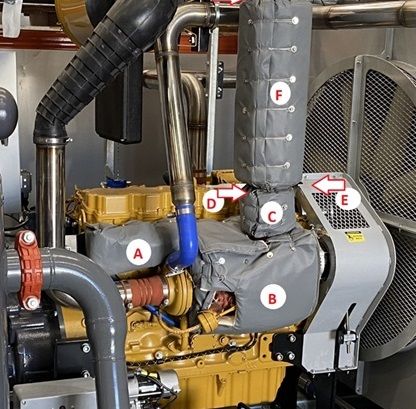

Why Use Them Fire Prevention: Stops oil leaks and fuel vapors from igniting on hot surfaces. Component Protection: Shields sensitive parts from extreme heat, extending their life. Worker Safety: Protects mechanics from burns during maintenance. Performance: Can help maintain optimal turbocharger and intake temperatures. Key Applications Engine & Exhaust Protection: Installed on turbochargers, exhaust manifolds, pipes, and mufflers to prevent fires caused by hydraulic, oil, or fuel leaks contacting hot surfaces. Asset Protection: Reduces radiant heat in the engine bay, protecting wiring looms, sensors, and nearby electronics, which extends the lifespan of components. Operational Efficiency: Keeps exhaust gas temperatures higher, which can help reduce Diesel Particulate Matter (DPM) and improve turbocharger efficiency. Personnel Safety: Reduces surface temperatures to prevent accidental burns to maintenance crews. Environmental/Fixed Infrastructure: Used on steam lines, tanks, and reactors in processing plants for energy efficiency. Key Industries & Applications Oil & Gas & Petrochemical: Insulating refinery pipes, valves, pumps, and offshore equipment to reduce heat loss and improve safety. Power Generation: Covering turbines, generators, and exhaust systems in power plants to control heat and improve efficiency. Manufacturing: Insulating extruders, injection molding machines, furnaces, and ovens to maintain process temperatures and save energy. Marine & Transport: On ships and heavy vehicles (trucks, buses) for engine/exhaust insulation to protect crews, reduce fire risk, and improve A/C performance. Mining: Critical for preventing fires on mobile equipment by covering hot exhaust components, and also used in processing plants. Food & Beverage/Pharmaceutical: Providing removable insulation for clean, consistent temperature control in processing equipment. Aerospace: Used for high-temperature protection in various components Types of Thermal Covers Exhaust Blankets/Wraps: Physical barriers for hot exhaust pipes and turbochargers to prevent contact with flammable materials and reduce engine bay temperatures. Heat Shields: Aluminium barriers that reflect radiant heat, applied directly to surfaces like firewalls and floor pans. Fire Sleeves: Highly insulating sleeves for hoses and cables, offering extreme heat and flame resistance. |